Understanding Counter Rotating Twin Screw Extrusion

IntroductionCounter rotating twin screw extruders function as positive displacement pumps, closely resembling gear pumps. In the realm of twin screw extrusion, these machines play a pivotal role in the processing of PVC (Polyvinyl Chloride) or C-PVC (Chlorinated Polyvinyl Chloride). Throughout this intricate process, the material undergoes a series of transformative steps: heating, conveying, compressing, degassing, plasticizing, shearing, kneading, and homogenizing. These steps are critical for achieving the optimal fusion of PVC or C-PVC, ensuring the structural integrity of products such as pipes, profiles, or sheets. To attain homogenous fusion, it is imperative that both dispersive and distributive mixing occur through shear and temperature adjustments, all within the confined spaces between the two screws and the screws and the barrel.

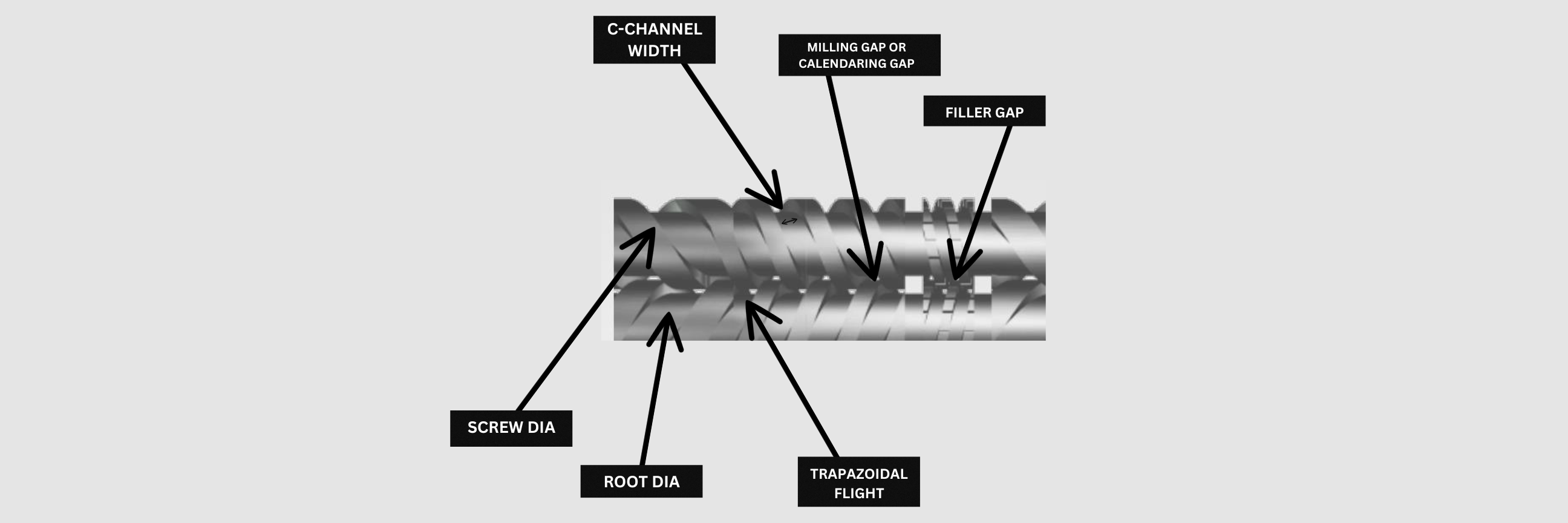

In the realm of counter rotating twin screws, the size of a parallel extruder is determined by the screws' diameter, whereas conical screws' size is defined by the screw's diameter at the end of the metering section. This specific diameter at the bottom of the channel is known as the "Root diameter." Understanding these gaps is essential for comprehending the nuances of PVC processing.

1. Milling Gap or Calendaring Gap The milling action predominantly transpires at the "milling gap." Here, the material is sheared between the flight tip of one screw and the channel bottom of the other screw, which rotate at the same RPM but different linear speeds. The amount of work imposed on the material and the resulting temperature rise are primarily controlled by the size of the gap and the screw's speed. This incremental process efficiently elevates the entire mass of material to the desired temperature in a controlled manner.

2. Filler Gap The flights within the twin screws are typically trapezoidal, with the narrow flight tip only partially filling the opposing screw channel during the initial stages of intermeshing. These trapezoidal flights effectively close off the channels at the midpoint between the two screw centers, satisfying the conditions for good pumping. However, this still leaves two channels of variable width between the screws as they approach this midpoint. This region is known as the "filler gap." The drag flow generated by the counter-rotating screws' flanks pulls the material into these channels, and the high pressure at the bottom aids in this process. This interaction results in shear mixing and material interchange between the screws, moving from high-pressure regions to low-pressure areas in the respective opposing channels.

3. Clearance Gap The clearance gap, as the name suggests, is the space between the screws and the barrel. A larger gap implies less material conveying and, consequently, a lower output. Over time, wear and tear can create this gap, which is typically rectified in conical screws by advancing the screws. Generally, a 0.5 mm gap is ideal.

The Mixing Process During Twin Screw Extrusion

Mixing is a crucial aspect of the twin screw extrusion process but comes at the cost of pumping and energy efficiency. Achieving the right balance between over-mixing and under-mixing is essential. Leakage flows also play a role in the mixing process:The volume of leakage depends on factors like the size of the gaps, pressure drop across the gaps, and the material's viscosity, which is influenced by temperature and the K value, especially in the case of UPVC (Unplasticized Polyvinyl Chloride).

In the final phase of mixing, the advancing material experiences backflow due to the back pressure from the die, reducing the output by about 20%. This backflow occurs through several areas: a leakage over the screw flights (clearance gap), through the gap between the flanks of the screw flights (filler gap), and through the milling gap. These actions ensure that all material is subjected to sufficient shear for effective distributive mixing. To further enhance mixing, cutout sections in the flights or pins can be employed.

Promoting Mixing Action

Twin screw extruders essentially function as "gear pumps." However, if they were used solely for pumping, no mixing would occur. While some shear occurs at the barrel wall, twin screw extruders operate at lower speeds than single screw extruders, resulting in lower shear rates and, consequently, reduced mixing action. To encourage mixing, adjustments can be made:

These modifications promote material interchange between the screws, further enhancing the

mixing process. In certain cases, mixing can also be achieved by interrupting the flights

or by cutting out portions of flights, breaking up laminar patterns.

This comprehensive understanding of counter rotating twin screw extrusion and the

intricacies of the process are vital for optimizing PVC processing and ensuring the

quality of the final products.

In Conclusion

Counter rotating twin screw extrusion is a multifaceted process that involves a combination of milling, filler, and clearance gaps to achieve the desired mixing and fusion of PVC materials. By understanding these gaps and the critical factors that influence them, manufacturers can better control the quality and efficiency of their PVC processing. With this knowledge, the industry can continue to innovate and produce high-quality PVC products for a wide range of applications.