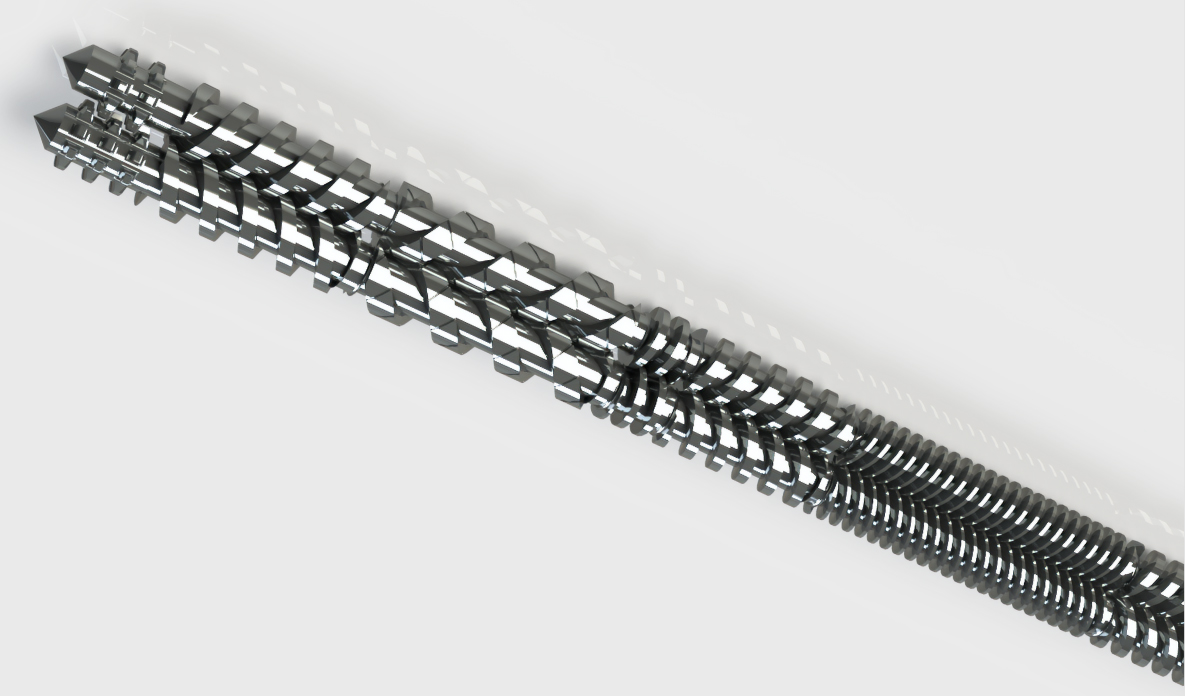

A twin screw barrel extruder is the classic machine used for the plastic extrusion process when two or more ingredients are mixed or compounded mainly for producing PVC Pipes. The process is best suited when extruding reactive polymeric materials. A twin-screw extruder is particularly useful in the production of rigid PVC and wood fiber blends. In this method, two screws rotate with or against each other and have special mixing features such as kneading block and forward and reverse capabilities, etc.

In a single-screw machine, friction between the resin and the rotating screw makes the resin rotate with the screw, and the friction between the rotating resin and the barrel pushes the material forward, and this also generates heat. Increasing the screw speed and/or screw diameter to achieve a higher output rate in a single-screw extruder will therefore result in a higher buildup of frictional heat and higher temperatures.

In contrast, in twin screw barrel extruders with intermeshing screws, the relative motion of the flight of one screw inside the channel of the other pushes the material forward almost as if the machine were a positive displacement gear pump which conveys the material with very low friction. In twin screw barrel extruders, heat is therefore controlled independently from an outside source and is not influenced by screw speed. This fact becomes especially important when processing a heat-sensitive plastic-like PVC.

Compared to single-screw extruders, twin-screw extruders are more efficient in providing homogeneous mixing of different ingredients such as additives, fillers, and liquids. The mixing efficacy of single-screw extruders could be improved by using mixing elements but not as effective as twin-screw extruders. A larger variety of twin-screw extruders are available that may vary in construction, could have parallel or conical screws that may rotate in the same direction (corotating) or opposite direction (counter-rotating), and have different degree of intermeshing.

The diverse range of screw extruders is manufacture from premium quality materials. Machine with sophisticated features is available at reasonable rates. Customized twin-screw extruders are also manufactured as per the requirement of customers in different industries. Machines are available that are designed to be easily synchronized with drives of the extruder and haul off resulting in high output at low screw speed and less consumption of power, easy operation, etc.

A new and advanced range of twin-screw extruders is supplied in the market. One such innovative product is the conical twin-screw extruder for dual conduit pipe that is capable of producing a twin pipe out of one mold. And the hi-tech machine is the kneading extruders that are the most important due to their various applications in industries and serious economic. This type includes single-screw and multi-screws.

In a twin-screw or multi screw extruder, there are two screws. Even is modestly sized extruders, these screws are highly efficient devices capable of the process several tons of plastic per hour. The flexibility of twin-screw extrusion equipment allows this operation to be designed specifically for the formulation being processed. For example, the two screws may be corotating or counterrotating, intermeshing or non-intermeshing. In addition, the configurations of the screws themselves may be varied using forward conveying elements, reverse conveying elements, kneading blocks, and other designs to achieve particular mixing characteristics.

We also make custom design as per your need. All Twin Screws are Nitrided for better life quality, but the life can be elongate by using our bimetallic screws with TC coted Twin screws.