Screws are one of the most important hot parts of any plastic extruder/injection

moulding or food processing plants. Since many decades, screws have been used for

feeding purposes, but due to large

amounts of research and development screw designs have changed drastically to make

the extrusion process more and

more efficient. At Tirupati Industries, we manufacture with the great

precision, a wide variety of screw designs:

At Tirupati Industries, we manufacture all kinds of single screw design ranging from 20mm to 180mm in diameter and to 6000mm in length for below mentioned applications.

Warranty: We give warranty of 1 to 1.5 year in our Single Screw

Material: EN41B MUSCO procured from authorized dealer

Nittriding Hardness: 67 to 68 HRC

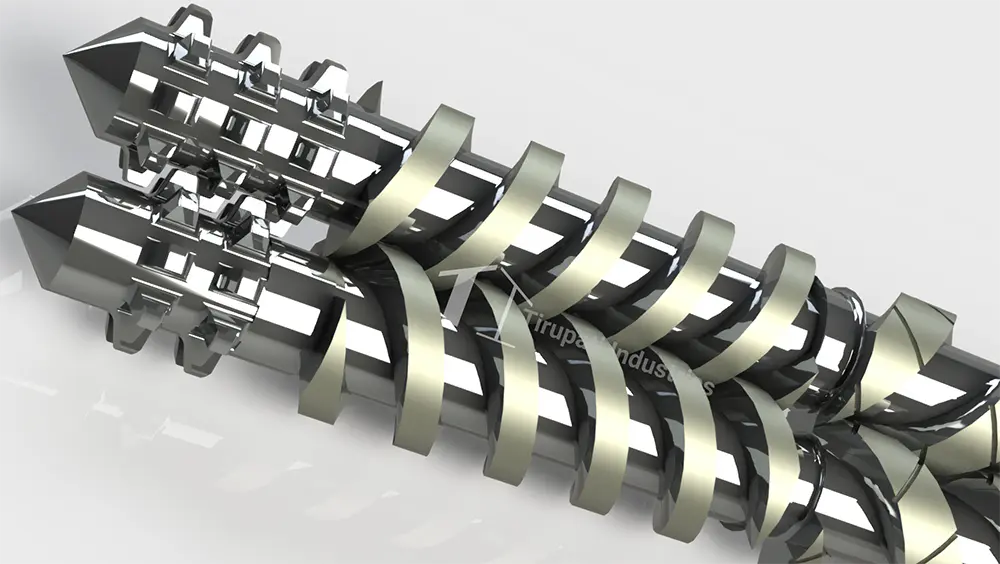

In many applications where higher output and better mixing is required, following screw designs can be provided with great accuracy and quality at Tirupati industries.

At Tirupati industries, We manufacture a wide range of Twin

Screw diameter ranging from 52mm to 110mm with output

capacity ranging from 110 to 900 kg/hr.

While manufacturing, We also take in consideration of market

needs such as low filler, high filler and ISI grade.

Warranty: We provide warranty of 1 to1.5 year in our Twin Screw

Material: EN41B MUSCO procured from authorized dealer

Nittriding Hardness: 66 to 68 HRC

At Tirupati Industries, We also manufacture vented screws used to extract volatiles from plastic material, ranging from 70mm to 120mm in diameter. The length depends on the design of the screw.

Tirupati Industries has capacity to provide the best Bimetallic screws by doing various types of TC coating on screws. This ensures the better life and higher working efficiency of the screw.

We provide bimetallic coating as per the economical need of the customer. We have divided our coating in two parts as shown below:

The melt section of any screw will acquire a high amount of wearing. Which leads to low output of the extruder. In order to solve this problem, we provide the Tungsten carbide coating in the melting zone using HVOF technology.

If you want your screw life to be doubled, we have the perfect solution for you. At Tirupati industries, we have two types of fully encapsulation options

With full encapsulation HVOF, we give you surety

of the double life for your screws.

With this new technology, we give you similar advantages like the full encapsulated HVOF coating at lower price. In this the thickness of the coated layer is lower than HVOF but ensures the quality of product.