Determining the Optimal Rotation Direction for Counter Rotating Twin Screws in PVC Processing

IntroductionThe primary goals of twin screw extruders in handling PVC/C-PVC are to achieve prolonged production runs of high-quality products—pipes, profiles, or sheets—with minimal thickness variation, reduced costs, and less wear and tear on the screw and barrel components.

Twin screw extruders typically consist of two intermeshing counter-rotating screws enclosed within a corresponding barrel, available in parallel or conical configurations. These operate akin to positive displacement pumps, functioning independently of frictional criteria. Throughout the twin screw extrusion process for PVC/C-PVC, the material undergoes conveyance, compression, degassing, plastication, shearing, kneading, optimal fusion, and homogenization before reaching the die.

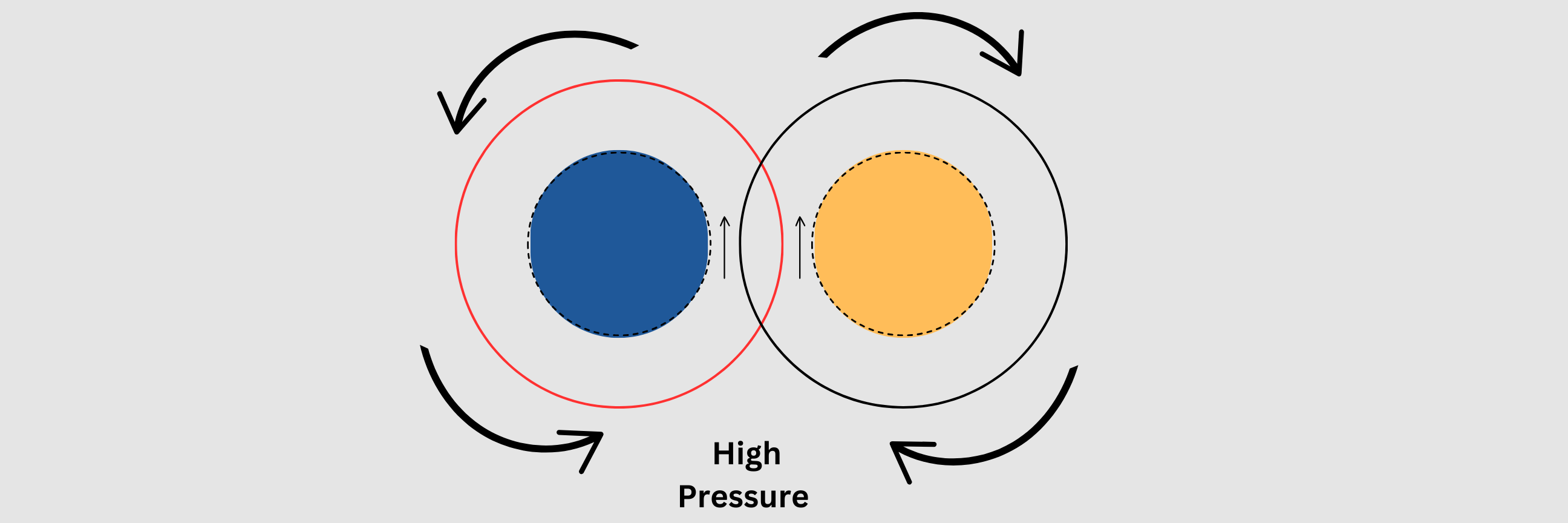

In counter-rotating screws, two possible rotation directions are observed from a top-down view:

1. Rotating Screws Toward the Center: - The inward rotation might efficiently draw material from the hopper into the screw bite. - However, there's a risk of foreign objects being pulled into the screws, potentially causing damage. The preference often leans toward screws rotating away from the center due to this safety aspect.

2. Rotating Screws Toward the Sides: - This rotation direction is more popular for several reasons: a. Easier filling of screw channels as material is drawn along the sides to fill the bottom. b. The bottom's high-pressure region and the top's low-pressure region at the wedge point are established, facilitating gas venting in the degassing section (decompression zone). c. The lower pressure at the top facilitates efficient gas removal from the milled material passing through the screw gaps—eliminating HCl, moisture, air, and volatile components. d. The dispersed and degassed material moving upward due to high bottom pressure, supported by the flanks of counter-rotating screws, contributes to milling and mixing the entire PVC compound incrementally. e. When used correctly, this configuration ensures gentle PVC processing within twin screw extruders.

Determining the ideal rotation direction for counter-rotating twin screws involves weighing the advantages and technical considerations associated with inward and outward rotations for effective PVC processing.